|

Zhengzhou Dehong Machine Manufacturing Co., Ltd

|

magnetic separation from China

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

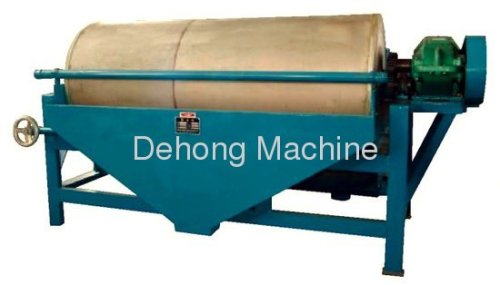

Dehong ISO authorized Wet-type CTB type Magnetic Separator for non-metal ores

Introduction of High efficient magnetic separator for selecting iron and manganese ore

This series of products is mainly used in wet magnetic sepatation of materials with granunarity below 3mm like magnetite, pyrrhotine, bake ore and washing tonite. It is also used for droning materials like non-mental ores, coal and building materials. Average magnetic induction of barrel surface is 100-600mT. According to customers' demands, it can provide magnetic separation with different magnetic induction like forward flow, semi counter flow and counter flow. The products have features, such as simple structure, high yield, convenient operation and easy maintenance.

Structure of High efficient magnetic separator for selecting iron and manganese ore

Series CTB wet drum permanent magnetic separator consists of magnetic drum, tank body, support, feed box, discharge box (ore concentrate box), drive motor, motor reducer, control box, etc.

The magnetic drum is made of stainless steel (thickness: 3mm) and covered with wear resistant rubber.

Working principle of High efficient magnetic separator for selecting iron and manganese ore:

When the raw materials flow into the tank body of the wet drum magnetic separator, firstly, the flowing direction of the raw materials is the same as the rotary direction of the magnetic drum, the iron magnetite materials are attracted to the surface of drum. This is the first separation. In the second step, the flushing water below flush the raw materials back for the second separation. This time the flowing direction of the raw materials is opposite to the rotary direction of the magnetic drum. Then along with the rotation of drum, the iron magnetite materials on the surface of drum will finally leave the magnetic field and fall to the ore concentrate box under gravity. Also, the flushing water above helps to flush the iron magnetite into the ore concentrate box. The weak magnetic and non-magnetic materials can not be attracted and will flow to the discharge pipe for tailings.

Main technical parameter of High efficient magnetic separator for selecting iron and manganese ore:

When the raw materials flow into the tank body of the wet drum magnetic separator, firstly, the flowing direction of the raw materials is the same as the rotary direction of the magnetic drum, the iron magnetite materials are attracted to the surface of drum. This is the first separation. In the second step, the flushing water below flush the raw materials back for the second separation. This time the flowing direction of the raw materials is opposite to the rotary direction of the magnetic drum. Then along with the rotation of drum, the iron magnetite materials on the surface of drum will finally leave the magnetic field and fall to the ore concentrate box under gravity. Also, the flushing water above helps to flush the iron magnetite into the ore concentrate box. The weak magnetic and non-magnetic materials can not be attracted and will flow to the discharge pipe for tailings.

Main technical parameter of High efficient magnetic separator for selecting iron and manganese ore:

Model | Shell diameter(mm) | Shell length(mm) | Shell rotation speed(r/min) | Feeding size(mm) | Processing capacity(t/h) | Power(kw) |

CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Magnetic Separation

Bone China

Separation Pad

Bone China Cup

Bone China Mug

Bone China Tea Set

More>>