|

Zhengzhou Dehong Machine Manufacturing Co., Ltd

|

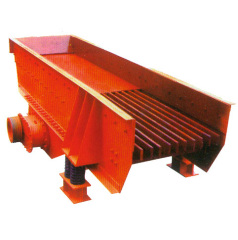

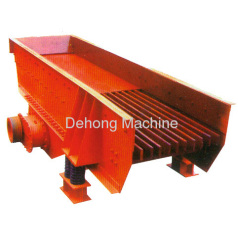

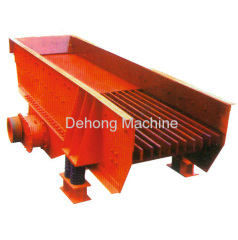

GZD-1200×4900 mining machinewith CE certificate manufacturer

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Long-life, low noise, low power consumption

Excellent performance, no flushing phenomenon of materials

Easy maintenance and low operating

Introduction of vibrating feeder:

This machine is placed before primary crusher machine, it feeds the bulk material to the primary crusher machine, at the same time, it can remove soil or impurities and control the feeding capacity, it is the necessary machine in the production line. It has firm structure, impact-resistant, wear-resistant characteristics.

GZD vibration feeder consists of frame body, vibration motor, spring, support seat and wear-resisting liner and so on.

GZD vibration feeder consists of frame body, vibration motor, spring, support seat and wear-resisting liner and so on.

The Vibrating Feeder (Vibratory feeder) is mainly used in feeding materials before coarse crushing. Our GZD series machine can put the block or granule materials from the material storage into the charging device in time evenly and continuously. Therefore, it can realize even feeding for crushers in sandstone production line and make rough screening of materials.

Working Principle of Vibrating Feeder:

There are two eccentric shafts rotating at high speed at the same time from opposite directions, thus the strong centrifugal force is formed. The component forces of centrifugal force along the vibrating direction will always overlap each other, then counteract with that of vertical force from vibrating direction, then exciting force along single direction is formed to drive the feeder vibrate along straight line. When materials are fed into the feeder, they may be thrown up and move like Para curve, then fall down. The materials will move forward on the slope surface of the feeder.

Vibrating Feeder (Industrial Vibrator) Application

Vibrating Feeder is a kind of linear direction feeding equipment. It features smooth vibrating, reliable operation, long service life and being suitable for feeding. Vibrating feeders are widely used in mining, building-material, silicate andchemical industry in the crushing and screening plants.In the Sand-Stone production line, vibrating feeder can send materials to crusher

evenly and continuously and at the same time, it can screen materials roughly.Vibrating feeder can be used in these areas such as metallurgical industry, coal mining industry, mining-selecting, building, chemical and grinding industry, etc.

Model: GZD-1200*4900 Max Input Size(mm): 650 Capacity(t/h): 200-430

Moter Power(kw):15 Overall Dimension(mm): 3850*1950*1630

Weight(kg):4500 Size of Funner(mm): 1200*4900

Moter Power(kw):15 Overall Dimension(mm): 3850*1950*1630

Weight(kg):4500 Size of Funner(mm): 1200*4900

Contact with me for details, if you have any questions.

Our company mainly produce and export:

1. Briquette making machinery: Mineral Briquette machinery, Coal Ball Pressing Machine, Belt Conveyor, Feeding machinery, drying machine, etc

2. Rotary Drying Plant: Sand and Gravel Production Line, Powder Rotary Drying Plant, Rotary Kiln, lime production line, cement production line, Magnalium production line,etc.

3. Mining machinery: Crusher, ball mill, flotation machine, etc.

2. Rotary Drying Plant: Sand and Gravel Production Line, Powder Rotary Drying Plant, Rotary Kiln, lime production line, cement production line, Magnalium production line,etc.

3. Mining machinery: Crusher, ball mill, flotation machine, etc.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Ce Approved

Adapter With Ce

Ce Electric Scooter

Ce Electric Bicycle

Ce Electric Bike

Ce Chain Saw

More>>