|

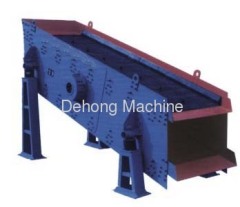

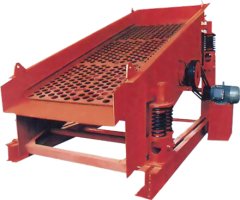

Zhengzhou Dehong Machine Manufacturing Co., Ltd

|

screening machines for sale screening machinery

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

High-Frequency Screen consists of vibration exciter, ore pulp distributor, screen frame, machine frame, suspension springs and sieve, etc.

Smooth vibration and Reliable working High-Frequency Screen

(1) Structure of High-Frequency Screen:

High-Frequency Screen consists of vibration exciter, ore pulp distributor, screen frame, machine frame, suspension springs and sieve, etc.

(2) Application of High-Frequency Screen:

This series screens are always used in processing minerals such as ferrous metals including hematite & magnetite and nonferrous metals including Lead, Zinc, Gold and Silver etc. This machine works in a re-circulating network with ball mill, which can upgrade the fineness of ferrous and nonferrous metals. Its efficiency is twice as that of Spiral Classifier.

(3) Features of High-Frequency Screen:

High efficiency, small amplitude and high frequency of screening; it differs from the conventional screens with breaking of the surface tension of pulp and small granularity high speed vibration on sieve cover and accelerates the separating of large-density useful mines and increase the contacting probability of the materials smaller than output granularity and the sieve pore. Therefore produce good condition and make the materials smaller than the output granularity, especially the big-density materials and pulp get through the sieve pore together.Its screen is made of stainless steel or nylon.

The obliquity of the sieving is adjustable. If the obliquity is close to 55º, end product with fineness of 300 mesh occupies 75%.

Main technical parameter of High-Frequency Screen:

The obliquity of the sieving is adjustable. If the obliquity is close to 55º, end product with fineness of 300 mesh occupies 75%.

Main technical parameter of High-Frequency Screen:

Specification | Sieve Mesh(mm) | Feeding Size (mm) | Screen Obliquity | Swing | Frequency (r/min) | Motor Power(kw) |

1200×2000 | 0.15~0.25 | <1 | 15º~55º | 0.6~2.2 | 3000 | 0.25 |

1500×3000 | 0.15~0.25 | <1 | 15º~55º | 0.6~2.2 | 3000 | 0.37 |

2000×3000 | 0.15~0.25 | <1 | 15º~55º | 0.6~2.2 | 3000 | 0.37 |

2200×3800 | 0.15~0.25 | <1 | 15º~55º | 0.6~2.2 | 3000 | 0.37 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Window Screening

Insect Screening

Screening Machine

Screening Plants

Screening Mesh

Galvanized Window Screening

More>>